High Quality Automatic Bottling Filling Aluminum Foil Sealing Machine for Liquid Milk Juice

Basic Info

| Model NO. | RXXGF |

| Filling Principle | Negative Pressure |

| Packaging Container Lifting Structure | Chute Lifting |

| Structure | Rotary |

| Packaging | Bottle |

| Packaging Material | Plastic |

| Bottle | PE Bottle, HDPE Bottle |

| Bottle Material | PE Material |

| Bottle Size | 180ml-2L |

| Bottle Cap | Aluminum Foil |

| Bottle Shape | Customized |

| Filling Technology | Gravity Filling |

| Bottle Neck | 28mm, Customized |

| Guarnatee | 1 Year |

| Transport Package | Film Wrapping Plus Sea Worthy Case Case |

| Specification | CE, ISO, UL |

| Trademark | Sunswell |

| Origin | Jiangsu, China |

| HS Code | 8422301090 |

| Production Capacity | 5-10 Sets/Month |

Product Description

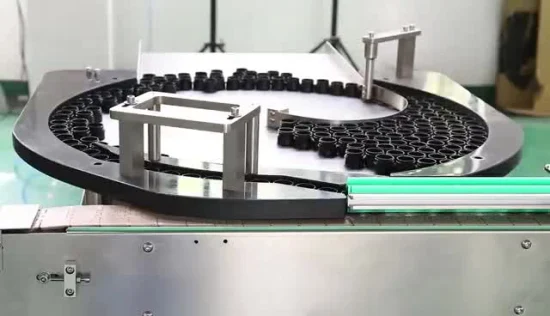

High Quality Automatic Bottling Filling Aluminum Foil Sealing Machine for Liquid Milk JuiceThis PE bottle filler capper is special designed for PP or PE bottled drink, such as juice and dairy product, bottle enter into rinser through inlet screw and turning upside down gripper, then to washing angle of the circle, after washing(time is adjustable) to filler through transit star wheel, then the filling turret push the bottle up to filling valve through cam rail, then to foil seamer(inline make the foil cap), the seamer with the opition of induction seal and heat seal.

Features:

1) The machine has compact structure, complete control system, easy operation and high degree of automation

2) To change bottle shape, the operator only needs to replace the star-wheel, inlet bottle screw and arc guide plate

3) The parts contacting media are made from 304and have no process blind angles to enable easy cleaning

4) High speed filling valve, guarantees liquid has precise level and no waste is incurred

5) The capping head applies a constant magnetic torque device to secure capping quality and prevent damage to the bottle cap

6) The control system has the function of control producing speed, cap shortage detection, bottle block auto stop and production counting

7) The machine applies a highly effective cap arranging system that has complete self control and protective device

8) The machine is equipped with a complete overload protection device that can secure equipment and the operator effectively

9) Main electric components and pneumatic components apply world famous brand products

10) The machine's operation is controlled by an advanced touch-scree

1. Bottle infeed by combination of air conveyor and infeed screw. Equipped with bottle jam protection device.

2. Composed by Dispenser, rinsing clamp, rinsing water recycle, there is a fixed rinsing time, the empty bottle was held by a fixed track, rinsing, drying, then reaches the cleaning purpose.

3. The design of filling structure is reasonable and without hygiene dead angle,the run of equipment is stable,the control accuracy is within ±2mm.The filling valve material is SUS304,The filling system has liquid level automatic control. Filling valve lift is controlled by the valve elevator,after filling valve contact the bottleneck ,it start to fill. Bottle is conveying by the wheel in the filling part.

Machine Capacity:

3-in-1 Wahing Filling Capping for PE Bottle

No | Model | Capacity |

1. | 10-10-1 | 5000bph |

2. | 16-12-2 | 7000bph |

3. | 24-16-2 | 12000bph |

4. | 32-28-3 | 15 000bph |

5. | 40-36-4 | 24000bph |

4-in-1 Washing washing filling capping for PE Bottle

No | Model | Capacity |

1. | 10-10-10-1 | 5000bph |

2. | 16-16-12-2 | 7000bph |

3. | 24-24-16-2 | 12000bph |

4. | 32-32-28-3 | 15 000bph |

5. | 40-40-36-4 | 24000bph |

Please feel free to contact us if you're interested in our products!

Company Information:

Sunswell leads the market in the field of machinery with advanced technologies in terms of our beverage packaging.

We provide a wide range of beverage packaging products. Our machinery has the most comprehensive scope. We enjoy worldwide praise with 10 years of global marketing experience. We have a large number of customers worldwide and we have various end products.

Our product range covers all types of machinery for the packaging of liquid, including water, tea, juice, carbonated soft drink, energy drink, alcoholic drink, beer, edible oil, dairy products, etc.

We provide good quality and technology from raw material to bottled liquid. We are a good supplier, well known for developing innovative high-end products and new technologies.

Our company offers a complete portfolio of support and consulting services, from project engineering to customized solutions and after-sales services. We also provide production optimization, training and advisory services, even end product development. We are looking forward to establishing relationships with you in the near future.

Our Exhibition:

Why Choose Us:

1) Special designed secondary blowing system monitors in time pressure curve of bottle stretch process in each cavity to provide accurate and timely parameters for technical adjustment, which is more convenient for operators to adjust technical parameters.

2) Adopt manipulator transfer technology that cam mechanism has precise control. Catch and send preforms at high speed and the quality is reliable. Taking preform, sending preform, taking bottle and sending bottle match action of opening and closing mould to ensure that the movement process is exact and high efficient. Taking preform, sending preform, taking bottle and ranking bottle are finished automatically by manipulator, avoiding middle pollution.

3) The cam mechanism controls exactly opening and closing of mould frame. Special mould locking and pressurizing system and simple and firm mould frame structure can control independently the blowing parameters of each cavity. Good malfunction diagnosis function and special blowing structure ensure the sealing reliability under various pressure. The blowing pressure can be adjusted.

4) Stretch rod control exactly preform's axial stretch. The first blow and second blow control preform's vertical stretch. By precise adjustment of the first and second blow, the ideal distribution of bottle wall thickness can be achieved.

5) Break conventional design and adopt structure of coaxial rotary bushing with small cubage and light weight. Adopt two deep groove ball bearings to fix two ends to make outside sleeve and core axes concentric, to ensure that the rotary sealing ring is not easy to be damaged. At the same time, increase one water back channel to make the leakage water in Gore circle flows back along pipe, ensuring that the water distributor won't have leakage.

Certification:

Service:

Packaging & Shipping:

Packaging Forms:

Production Process:

Related Products:

FAQ:

Q1: which city are you in? how can I get to your factory? Are you a trading company or factory?

A1: We are in Zhangjiagang city, two hours driving from Shanghai. We are factory. Manufacturing mainly beverage filling and packaging machines. We offer turnkey solutions with more than 10 years experience.

Q2: Why is your prices higher than others?

A2: We offer high-end machines in our business. Welcome to our factory to have a visit. And you will see the difference.

Q3: What is your delivery time?

A3: Normally 30-60 working days depends on machines, water machines are faster, carbonated drink machines are slower.

Q4: How to install my machines when it arrives? How much the cost?

A4: We will send our engineers to your factory to install the machines and train your staff how to operate the machines If needed. Or you can arrange engineers to study in our factory. You are responsible for air tickets, accommodation and our engineer wage USD100/day/person.

Q5: How long time for installation?

A5:Subject to machines and the situation in your factory. If everything is ready, it will take about 10 days to 25 days.

Q6: How about the spare parts?

A6: We will send one year enough easy broken spare parts together with the machines for free, we suggest you buy more units to save international courier such as DHL, it is really costly.

Q7: What is your guarantee?

A7: We have one year guarantee and life-long technical support. Our service also including machine maintence.

Q8: What is your payment term?

A8: 30%T/T in advance as down payment, rest should be paid before shipping. L/C is supported also.

Welcome to click "SEND" below for more information!

Contact:

| Name | Flora |

| Company | Zhangjiagang Sunswell Machinery. |

| Tel | 0086 512 5850 1665 |

| Fax | 0086 512 5631 0082 |

| Cell | 0086 187 5282 9782 |

| Web | sunswell.en.made-in-china.com |