Automatic Flowmeter Filling Machine for Butter

Basic Info

| Model NO. | CD-QZD4 |

| Automatic Grade | Automatic |

| Material Type | Skin Care Products, Dairy Products |

| Filling Valve Head | Multi-Head |

| Feed Cylinder Structure | Single-Room Feeding |

| Dosing Device | None |

| Filling Principle | None |

| Packaging Container Lifting Structure | None |

| Structure | Linear |

| Packaging | Bottle,Barrel,Box,etc |

| Packaging Material | Electric |

| Weight | 650kg |

| Key Selling Points | Easy to Operate |

| Application | Skin Care Products, Dairy Products ,etc |

| Transport Package | Wooden Box |

| Specification | 1000*1000*1400mm |

| Trademark | Chengde |

| Origin | Qingzhou City, Weifang City, Shandong China |

| HS Code | 8422301090 |

| Production Capacity | 10-20 Sets Per Week |

Product Description

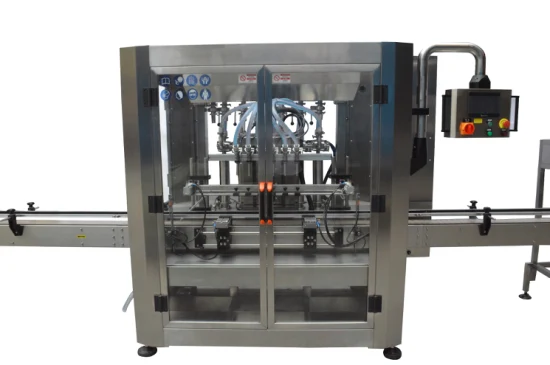

Product Introduction Automatic Roller Capping Machine for Skin Care Products, Dairy ProductsThe full-automatic flowmeter filling machine adopts German Siemens programmable controller (PLC) process control programming and automation; Touch screen man-machine operation interface is adopted, with complete functions, convenient, reliable and simple operation; The adjustable range of filling capacity is large, and the adjustment division value is 1ml; The filling and blanking forms include oblique punching or direct punching, which is suitable for filling with different liquid properties, oblique punching is suitable for liquid materials that are prone to foam, and the positioning form of filling nozzle includes plug-in or suspension, which is suitable for products with different filling heights.

Technical Parameters

| Dimensions | 1900x1600x2000MM |

| Filling volume | 1-20L |

| Power | 0.75--1.5KW |

| Filling capacity | 10-20 tanks / min (calculated by 1L) |

| Filling Accuracy | ≤±0.2% |

1. The filling machine adopts high-precision flowmeter and real-time temperature collection to compensate for the density change of oil due to temperature difference, so as to effectively ensure the accuracy of filling measurement2. Touch screen man-machine operation interface is adopted, with complete functions, convenient, reliable and simple operation; 3. the adjustable range of filling capacity is large, and the adjustment division value is 1ml; 4. the filling and blanking forms include oblique or direct punching, which is suitable for filling with different liquid properties. The oblique punching type is suitable for liquid materials that are prone to foam. The positioning form of the filling nozzle includes plug-in or suspension type, which is suitable for products with different filling heights;5. the form of liquid supply can be high-level tank or pump pressure, which greatly improves the production capacity;6. variable frequency speed regulation is adopted, and the fast pipe is mixed first and then the slow pipe, which can effectively solve the problem of steam foam bottle overflow during pump pressure rapid filling and ensure the filling accuracy;7. unique filling head design and vacuum back suction system ensure that on-site and packaged products are free from residual liquid pollution8. the well-known high-quality components are used for the matching of main electrical and gas components to ensure the reliability, accuracy, stability and durability of the system operation.

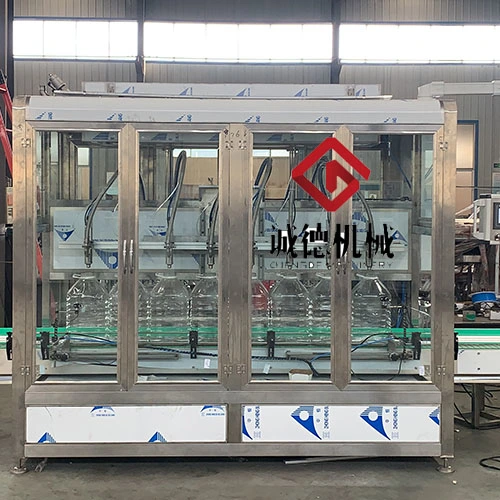

Detailed Images

Our Company

Our History

Qingzhou Chengde Packing Machinery CO., Ltd was founded in 1998, We are one of the early filling machinery manufacturing enterprises, covering an area of 6000 square meters, and has more than 30 employees. In order to better serve the intelligent packaging machinery of various industries at home and abroad, our employees are regularly trained and constantly improve their technical level. The workshop has newly invested CNC machine tools, large cutting machines, etc To expand production capacity and improve service capacity and service level.

Our Factory

Qingzhou Chengde Packing Machinery CO., Ltd is located in caterpillar Industrial Park. It is an enterprise specializing in the production, research and development, manufacturing, sales and service of automatic packaging machinery. Mainly engaged in a variety of filling machines, bottle washing machines, drying machines, sealing machines, labeling machines, inkjet machines, sealing machines and so on.

Our Product

Filling machine, bottle washing machine, dryer, capping machine, aluminum foil sealing machine, can sealing machine, labeling machine, inkjet machine, sealing machine and other automatic production equipment.

Our Service

The factory is responsible for making the progress plan of the project within one week after signing the contract to ensure the implementation of the project according to the time specified in the contract; without the consent of Party A, the schedule shall not be delayed. Our factory adopts the after-sales service mode of whole process telephone tracking for the supplied equipment.

Shipping&Delivery

1. good quality control2. timely delivery and long-term test before delivery3. continuous improvement of new technology4. customers are welcome to provide design and logo5. competitive price6. environmental protection products7. in various designs, small orders are acceptable

FAQ

Are you manufacturer?

Yes. We are one of leading manufacturers for Kinds of Weigh Filling Machine,Piston Filling Machine,Gravity Filling Machine,Flowmeter Filling Machine,Capping Machine & Sealing Machine,many

new production line,etc.

What advantages do you have?

(a).Punctual: Have your orders met with the latest delivery?

We are a manufacturer with so many advanced and new machines.It ensures we have the ability to carry out the production schedual for punctual delivery.

(b). We are factory specializing in the manufacture and export of many kinds of filling machines such as :Weigh Filling Machine,Piston Filling Machine,Gravity Filling Machine,Flowmeter Filling Machine,Capping Machine & Sealing Machine for about 24 years .We have professional designs ,and also our price is very competitive because we are mannu-factory ,we are the source .Are you a factory or a trading company?A1: we have our own factory, skilled workers and experienced R & D personnel; D and professional service team.Q2: how is your factory doing in quality control?A2: our quality is based on high-quality materials imported from developed countries. Our price is based on quality. We will give each customer a reasonable price.Question 3: what is the product range?A3: we can provide you with a variety of products for one-stop purchase. We can also customize it according to your specific situationrequirementQ4: how about after-sales service?A4: we can give you a one-year after-sales warranty, or we can send our engineers to your factory to install equipment and train your employees, but the buyer shall pay the expenses of round-trip air tickets, hotel accommodation and the seller's engineers. We will send you some free spare parts for replacement.Q5: if we buy from you, what is the guarantee?A5: all ordered equipment will be guaranteed for one year from the date of delivery.Q6: what kind of Lin do you produce?A6:1 cream production line2. Liquid cleaning production line3. Perfume production line4. Lipstick production line5. Aerosol production line6. Basic production line7. Toothpaste production line8. Soap production line

Contact Us

Qingzhou Chengde Packing Machinery

1.Contact Person:Frank Yue

2.Add: Qingzhou City, Weifang City, Shandong Province, ChinaIf you have any products demands to ask,Please don't hesitate to contact us at your convenience ,I will be always here! Automatic Roller Capping2 Machine for Skin Care Products, Dairy Products