Energy-Saving Gravity Filling Apple Vinegar Plastic Bottle Filling Machine

Energy-Saving Gravity Filling Apple vinegar Plastic Bottle Filling MachineThe Hot filling technology can expand producti

Basic Info

| Model NO. | CGF32 |

| Filling Principle | Vacuum |

| Packaging Container Lifting Structure | Pneumatic Lifting |

| Structure | Rotary |

| Packaging | Bottle |

| Packaging Material | Plastic |

| Filling Speed | 1000-20000bph |

| Bottle Volume | 100-2000ml |

| Suitalbe Fbottle | Pet Bottle /Glass Bottle |

| Transport Package | Wooden Case |

| Specification | 12CBM |

| Trademark | Newlink |

| Origin | China |

| HS Code | 8422301090 |

| Production Capacity | 100/Year |

Product Description

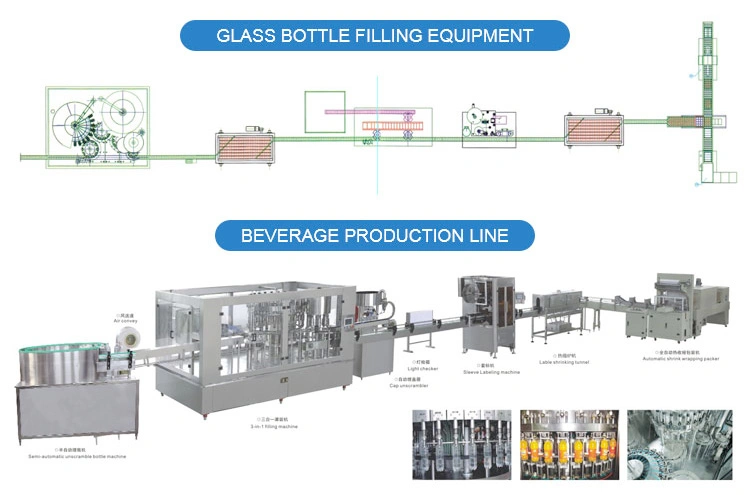

Energy-Saving Gravity Filling Apple vinegar Plastic Bottle Filling MachineThe Hot filling technology can expand production and packaging opportunities for juices, nectars, soft drinks, and teas. No matter your beverage type, our unmatched expertise helps you achieve more with extensive technical knowledge and packaging capabilities.TheHot Filling Lines is a unique PET packaging solution offering a great alternative for hot-filled beverages in PET bottles. It expands the opportunities of product premiumisation and revenue generation with no compromise on packaging performance and the consumer experience. This innovative solution is addressing the single serve market of Hot fill (juice, nectar, soft drink, , tea) filled in PET bottles up to 1.2L at a temperature of 70-88°C.WE Provide complete Filling solution for Hot Fill lines for juices, teas and energy drinks 1- More customisation and design freedom2- Fully process control with fewer operatorsTechnical Parameters

| MODEL | HCGF8-8-3 | HCGF12-12-6 | HCGF18-18-6 | HCGF24-24-8 | HCGF32-32-8 | HCGF40-40-10 | HCGF50-50-12 |

| Washing No | 8 | 12 | 18 | 24 | 32 | 40 | 50 |

| Filling No | 8 | 12 | 18 | 24 | 32 | 40 | 50 |

| Capping No | 3 | 6 | 6 | 8 | 8 | 10 | 10 |

| Capacity(500ml) | 2000BPH | 4000BPH | 8000BPH | 12000BPH | 15000BPH | 20000BPH | 24000BPH |

| Installed Capacity(kw) | 2 | 3.5 | 4 | 4.8 | 7.6 | 8.3 | 9.6 |

| Overall Size | 2000*1600*2400 | 2450*1800*2400 | 2650*1900*2400 | 2900*2100*2400 | 4100*2400*2400 | 4550*2650*24000 | 5450*3210*2400 |

| Air Conveyor:It made by SS 304/ with air fan for Empty PET bottle inlet ,it works with bottle filling machine ,Fast and Stable unscramble empty bottle for filling machine |

|

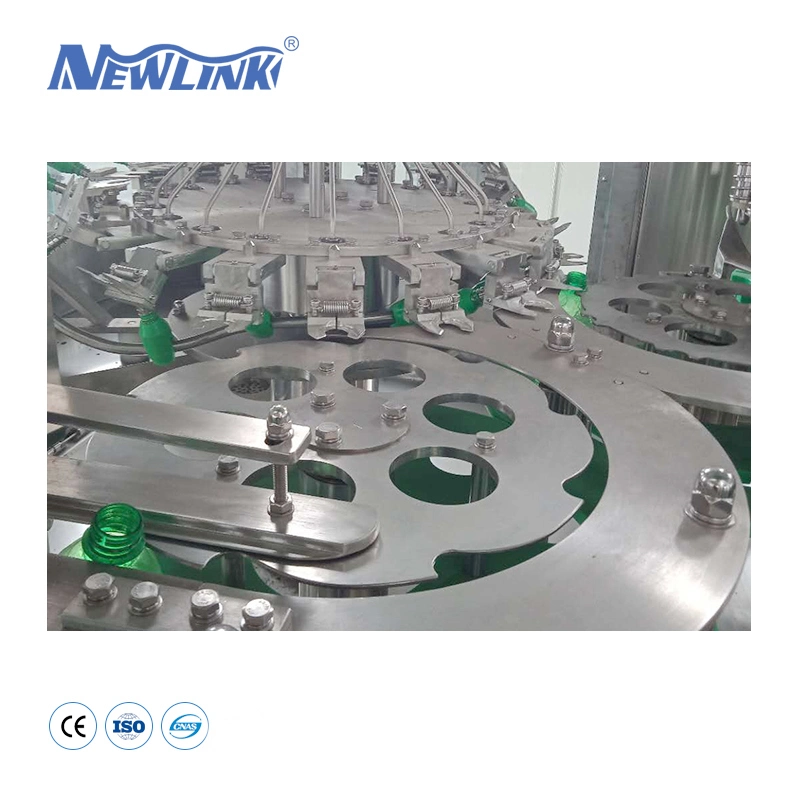

| Bottle washing parts:It is mainly composed of by bottle washing spray head, and SS guide rail. >>The bottle washing head rotates with U Shape fork parts, and the bottle neck gripper is used to hold the bottle neck, and the rail is flipped by 180°, rinsed and dripped, The bottle washing system uses the efficient cleaning spray nozzle which can be cleaned in every place of the bottle. |

| Filling parts: It adopts high precision, high speed and quantitative filling SS valve, and the liquid level is accurate without liquid loss to ensure excellent filling quality.It mainly consists of water tank, filling valve, guide rail and card bottle lifting device. After filling processing ,The valve closes by itself. |

|

| Capping parts:The capping head adopts constant torque device to ensure the sealing quality. and protect bottle cap during capping processing |

| Conveyor belt :Transducer is uesd in bottle entering chains to adjust speed to make the operation of moving bottle steadily and reliably. |

|

Auxillary Equipment

| Cooling System- Mainly for cooling and sterilization- The main parts of the machine are made of stainless steel, the top is designed to be openable for easy maintenance and observation- Nozzles are manufactured using U.S. technology and spray water evenly- Conveyor belt adopts Rexnor technology, flat surface with small wear- Smooth and reliable operation with low energy consumption

| |

| Bottle Inverter Chain - Use juice own high temperature to kill the bacterial inside cap.- Use juice own high temperature to improve sealing of bottle to extend warranty time.- Use SUS 304/316 stainless steel chain and high polymer material conveyor to keep high quality and increase service life. | |

| Automatic wrapping machineBENEFITS.1 / Pack consistency and quality2 / Gentle and precise infeed configuration3 / Flexible handling of multiple SKUs4 / Automatic pack and raw material changeovers5 / Heat, glue, carton and film optimisation

|

Our Service:1.Your inquiry related to our product & price will be replied within 24hours2.Well-trained & experienced staff are to answer all your inquiries in English of course.3.Working time: 8:30am ~6:00pm, Monday to Friday(UTC+8).4.OEM & ODM projects are highly welcomed. We have strong R&D team here to help.5.Your business relationship with us will be confidential to any third party.6.Good after-sale service offered, please get back if you got question. For more information ,Please feel free to send inquiry to us

Send to us