Vegetable Fruit Tray Packing Machine Snack Biscuits Cup Filling Aluminum Foil Sealing Machine

Basic Info

| Model NO. | BG60A |

| Forming Function | Filling, Seal |

| Driven Type | Pneumatic |

| Material Type | Paste |

| Packaging | Cartons |

| Packaging Material | Bamboo, Wood |

| Name | Linear Automatic Food Box Filling Heat Sealer |

| Product Name | Container Filling Sealer |

| Output | 3200-4000 Containers/ Hour(Can Be Customized) |

| Material | Stainless Steel |

| Dimension(L*W*H) | 2400*700*1700mm |

| Air Consumption | 0.8m3/Min |

| Tray Size | According to Customer`S Requirment |

| Function | Food Box Container Packing Machine |

| Suitable for | Box Cup and Various Shapes Sealing |

| Feature | Easy Operation |

| Sealing Method | Heat Sealer |

| Transport Package | Wooden Case |

| Specification | 800kg |

| Trademark | chunlai |

| Origin | Zhejiang, China |

| HS Code | 8422303090 |

| Production Capacity | 60 Sets/Month, 1600 Trays/Hour |

Product Description

Product Description

BG Linear Type Automatic Box Filling Sealing Packing Machine

Can be customized according to customer's demand

| Model | BG-2 | BG-4 | BG-6 |

| Production capacity | 1600 trays/hour | 3200 trays/hour | 4800 trays/hour |

| Voltage | Single phase 220V, 3 phase 220V3 phase 380V/400V/415V50Hz/60Hz | ||

| Power | 4KW | 5Kw | 6 Kw |

| Air consumption | 0.8 mз/min | 0.8 mз/min | 1 mз/min |

| Dimension | 2400×650×1650 mm | 2400×700×1700 mm | 3000×800×1700mm |

| Weight | 600Kg | 700Kg | 1000Kg |

Other Function

1. Manual put the box/Conveyor belt into the box2. Automatic roll film sealing/pre-cut foil sealing3. Automatic film cutting and waste film recycling4. Automatic out of the box

Machine Scope Of Application

| Filling for liquid ,paste,granule,powder,and so on.Sealing for cup,bottle,bowl,tray,can,jar,bucket etc... | ||

| Yogurt /Milk/ChocolateFilling Sealing Machine | WaterFilling Sealing Machine | JuiceFilling Sealing Machine |

| Jelly/PuddingFilling Sealing Machine | JamFilling Sealing Machine | SauceFilling Sealing Machine |

| Instant NoodlesSealing Machine | Tofu/BeancurdSealing Machine | CoffeeFilling Sealing Machine |

| Lunch boxSealing Machine | Frozen Food/MAPPackaging Machine | Potato Chips CanisterSealing Machine |

| PorridgeFilling Sealing Machine | Plastic JarSealing Machine | Plastic BucketSealing Machine |

| Wet Wipe CanSealing Machine | Dehumidifier BoxFilling Sealing Machine | Cosmetic/DetergentFilling Sealing Machine |

Recommended Machine

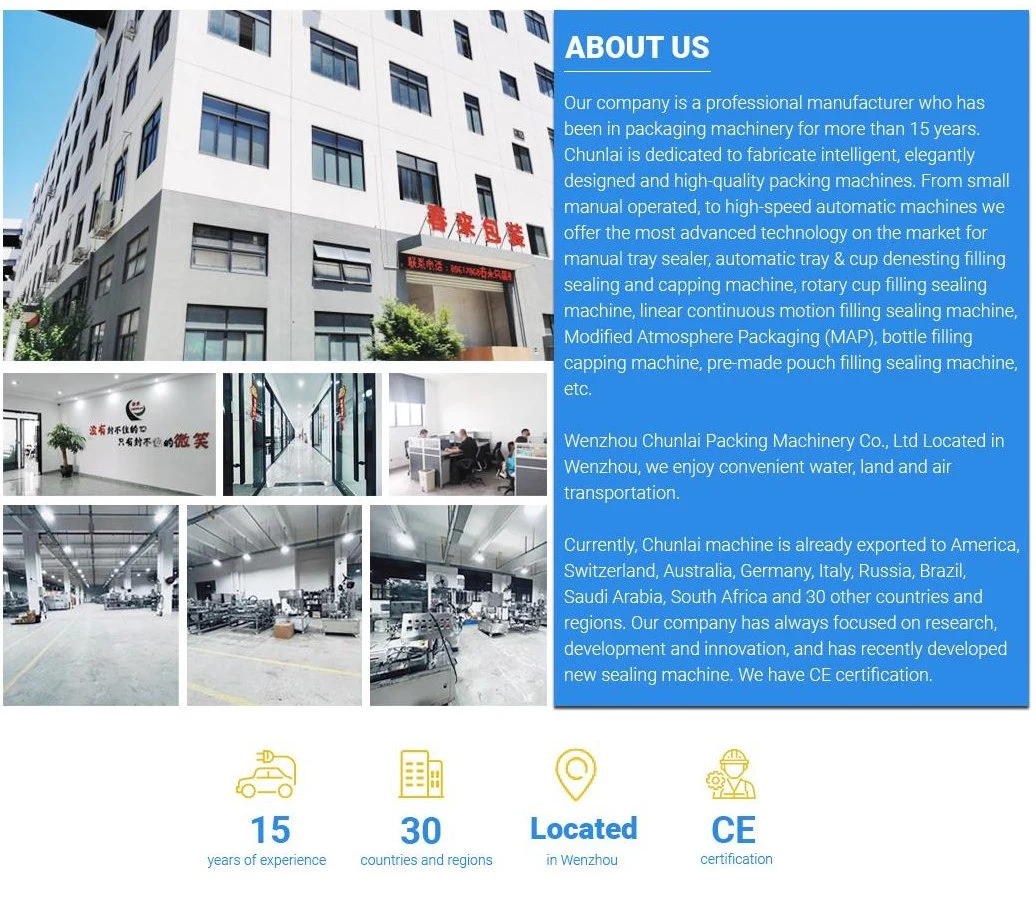

Company Profile

| Packaging | Shipping |

| First Rust inhibitor | First contact you the machine is ok |

| Second Wrap film | Second put the freight come and take the machine |

| Third Plywood cases | Third Plywood cases |

| Last in container | Last in container |

After Sales Service

1. Before sending the machine, we will test and adjust it so that you can use it directly after you receive it.2. The machine is packaged and shipped as a whole machine, without assembly.3. Send operation videos and instructions to customers to help them use the machine better.4. If there is any problem during use, we will give professional advice online.

FAQ

Q: First time import, how can I believe that you would send product ?

A: We are verified company by Made in China ,to make transaction success, we support and recommend LC or with visit our factory

Q: How to ensure that I received the machine undamaged?

A: First , we package is standard for shipping,then send you the photo when give the product to the freight forwarder. before pick up , please confirm product undamage, if damage, The ship company will take the responsibility

Q: What aftersales service or any question about products?

A: This machine enjoys 1 years warranty , any problem , I am on line from 9 am to 5 pm, or you can send me mail , will reply you within 12 hours, I'll give you detail instruction.