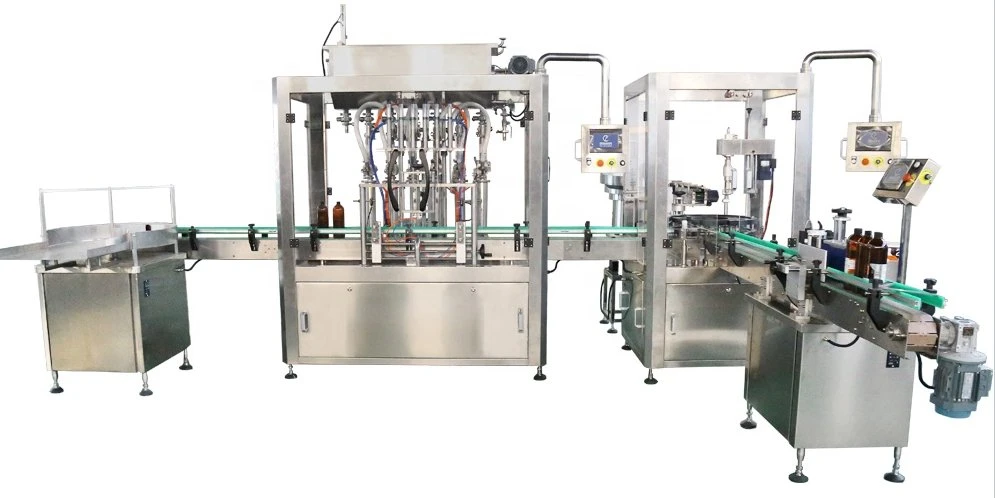

Automatic 4/6/8 Piston Pump Filling Machine for Tomato Sauce Glass Paste

Basic Info

| Model NO. | PX-BFC80 |

| Automatic Grade | Fully Automatic |

| Material Type | Liquid |

| Filling Valve Head | Multi-Head |

| Feed Cylinder Structure | Multi-Room Feeding |

| Dosing Device | Capacity Cup |

| Filling Principle | Atmospheric Pressure |

| Packaging Container Lifting Structure | Pneumatic Lifting |

| Structure | Linear |

| Packaging | Bottle |

| Packaging Material | Composite Materials |

| Accuracy | 99% |

| Function | Blowing, Filling, Capping |

| Material | Stainless Steel |

| Capacity | 2000 Bph or Customized |

| Drive | Servo System |

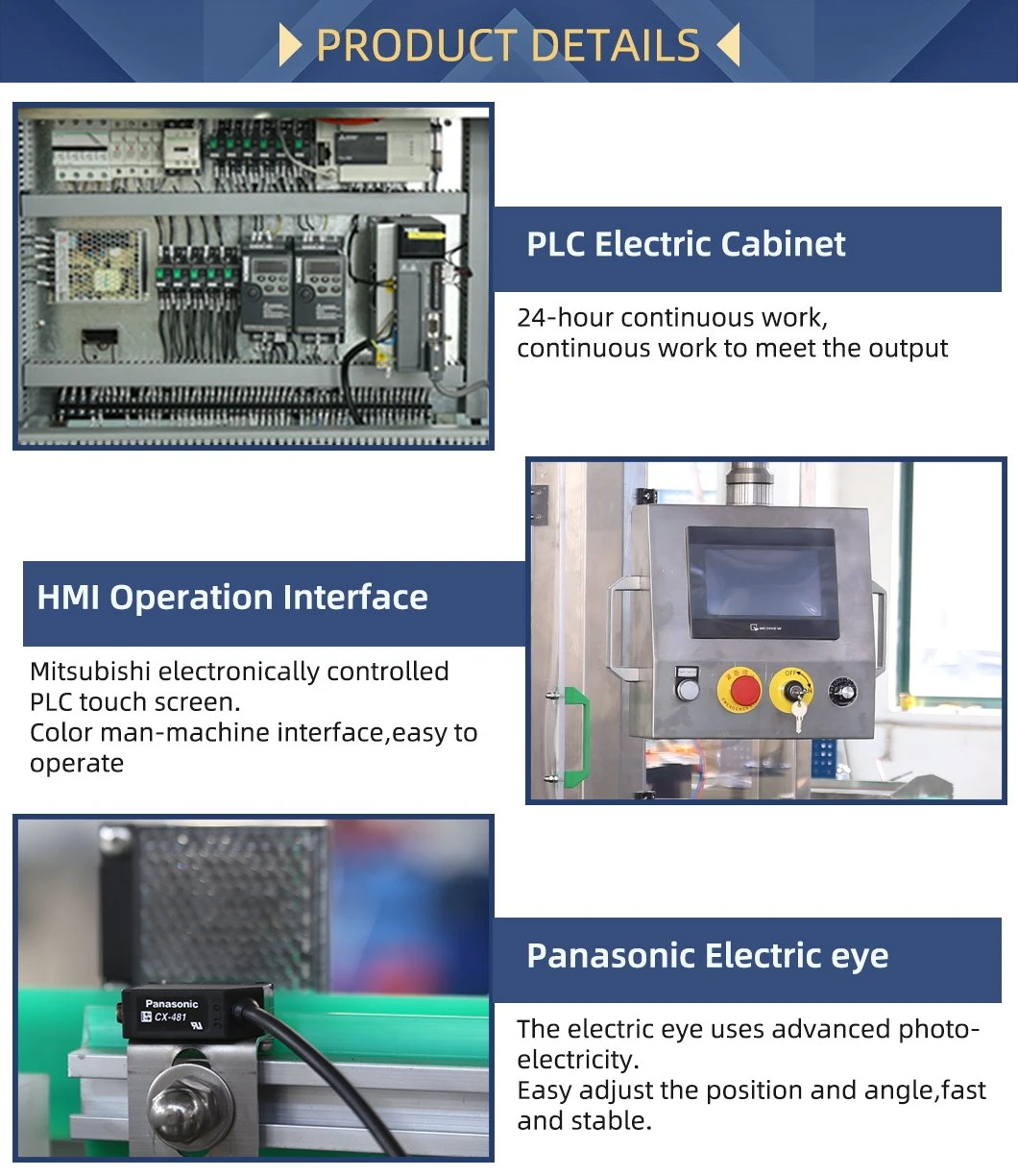

| Controlled | PLC |

| Transport Package | Strong Wooden Cases |

| Specification | 10-100ml filling machine |

| Trademark | shanghai PAIXIE |

| Origin | Shanghai China |

| HS Code | 8422309090 |

| Production Capacity | 3000 Bottles Per Hour |

Packaging & Delivery

Package size per unit product 2500.00cm * 1800.00cm * 1650.00cm Gross weight per unit product 800.000kgProduct Description

Overview

Product Description

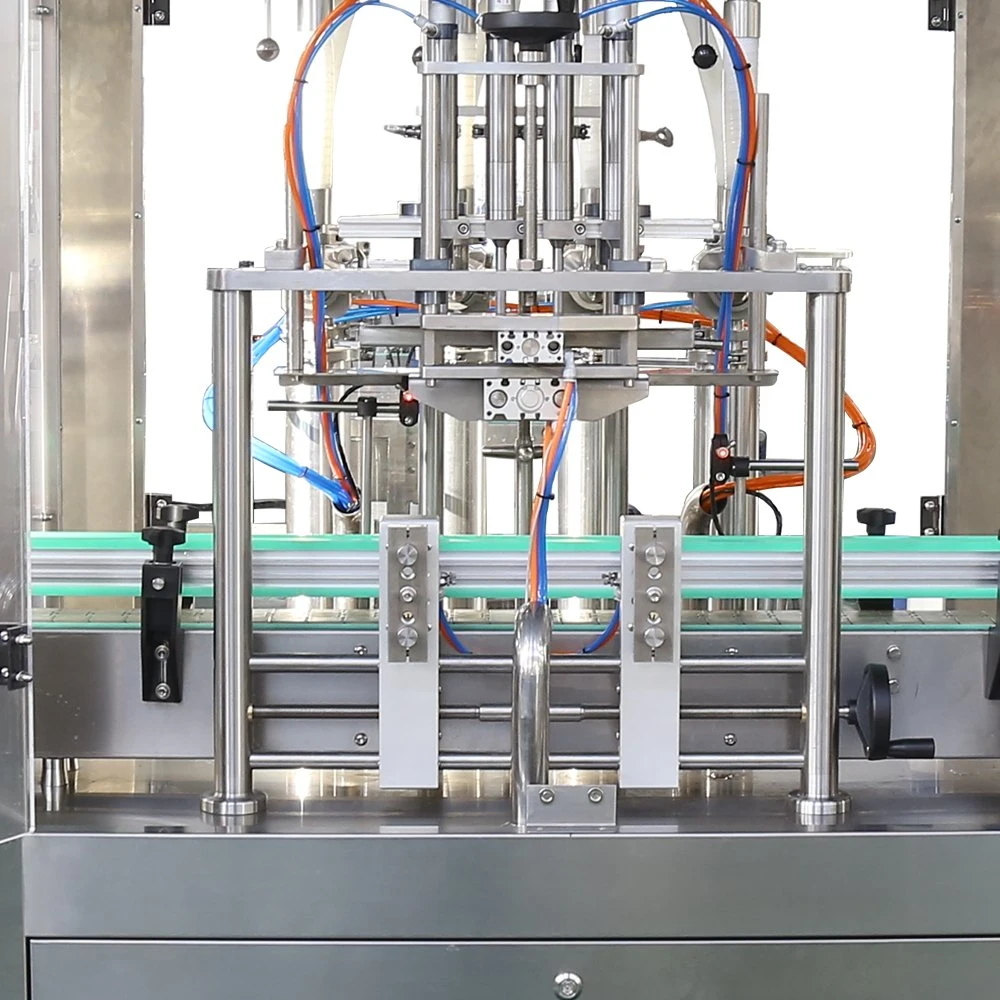

The new PX-BFC80 Smart Automatic tomato sauce honey jam glass jar paste servo driving filling machine is able to fill 30-40 fills per minute liquid products, depending on fill volume. Easy adjustable for 10-100 ml vials. The four nozzles filling station adopt piston pump, specially suitable for different viscous liquid materials, such as oil, perfume, syrup, etc. Driven by servo motor system, filling with high accuracy of ±1%. Insertion station includes closed cabinet with vibrating bowl feed for 10-50 mm diameter caps. No bottle, no filling, inserting or capping.

Product Parameters

| Model | PX-BFC80 |

| Filling material | tomato sauce honey jam glass jar paste etc |

| Yield(pcs/min) | 30-40 BPM (customized) |

| Filling heads | 1-4 (customized) |

| Filling pump | Piston pump |

| Capping heads | 1-2 (customized) |

| Work voltage | 110/220/380V 50/60HZ (customized) |

| Air presstion | 0.6MPA |

| Filling Accuracy | ±1% |

| Capping rate | 99% |

| Power | 2-3.5KW |

| Driving | Servo motor / Explosion proof motor (customized) |

| Direction | Left -rigth /right-left |

| Pump volume | 10-100 ml (customized) |

| United size | 1200*900*2000mm |

| Weight | 500kg |

| Material | Contacting parts SS304/SS316 (Optional) |

| HMI | 7.5" Color Touch Screen Control |

| Protection | Comprehensive Safety Alarm System |

| Speed controller | Variable Speed Controls |

| Detecting system | Vial Detector & Counter |

Detailed Photos

You may worry these

1- How can I fill so many formats my bottles with the machine perfectly without complex adjusment?

2- How can I understand your quality? I do not want any kinds bad machine which failed to live up to my investment.

3- How can I know your machine life? It looks always beautiful but only in your room.

4- How can I install such a big long machine by myself? It looks never easy at all.

5- How can I recognize the real difference in chinese market? So many suppliers quoted me every day!!!

6- What should I do if the machine is broken? Who is gonna to help me?

PAIXIE solution

Compared with traditional machinery, PAIXIE smart filler has characters below which are beneficial to each customer operation experience:

1- With servo driving , operator just edit the filling parameter on HMI to realize all kinds products packing.

2- 150mm width SS304 protection frame which equiped with induction switch is able to stop machine whenever operator open the plexiglass door which is good for human protection.

3- PAIXIE'S machines are all equiped with scale rules for diffeferent kinds bottle replacing , which is convenient for date recording and save the time in adjusting.

4- All PAIXIE'S machine are made of SS304+SS316 which avoiding pollution perfectly, protect the quality of customer's product.

5- Machines are delivered as whole which solving the stress of after-sale installation for customer . PAIXIE'S technicians are standing by all time for on-site service