Metal Roof Tile Ridge Cap Colour Coated Tile Roll Former Forming Pressing Making Machine

Basic Info

| Model NO. | ZTRFM |

| Tile Type | Glazed Steel |

| Certification | CE, ISO |

| Condition | New |

| Customized | Customized |

| Usage | Roof, Wall |

| Transmission Method | Hydraulic Pressure |

| Name | Ridge Cap Roll Forming Machine |

| Material | Gi,Gl, PPGL, PPGI |

| Blade | Cr12 |

| Roller | Chrome Plated |

| Oversea Warehouse | India, Russia |

| Plant Area | 200acres |

| Boss | 15 Yearexport Experience |

| Countries Serviced | More Than 200 Countries |

| Trade Ability | Top3 in Hebei |

| Machine Quality | High End |

| After-Sale Service | Provide Commissioning and Installation Work |

| Transport Package | Non Package |

| Specification | 9.5*1.45*1.5 |

| Trademark | ZTFRM |

| Origin | China |

| HS Code | 8455221000 |

| Production Capacity | 200set/Year |

Product Description

Ridge Cap Colour Coated Tile roll Forming Machine

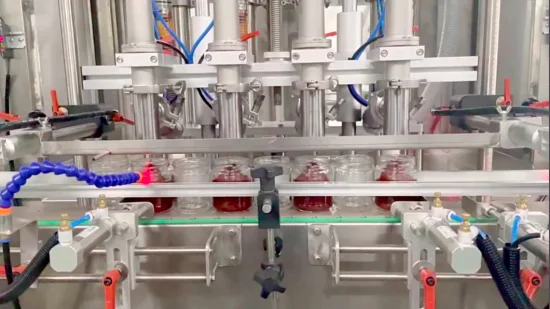

Product DescriptionRidge Cap Colour Coated Tile roll Forming Machine is used to produce metal roof ridge tile which is one type popular metal construction material,this material is usually used with other metal roof sheets,they are widely used in the construction of various industrial plants, villages, warehouses, supermarkets, hotels, exhibition, family construction, shopping malls shutter doors and etc.It has the advantage of beautiful, classical appearance and grace taste.

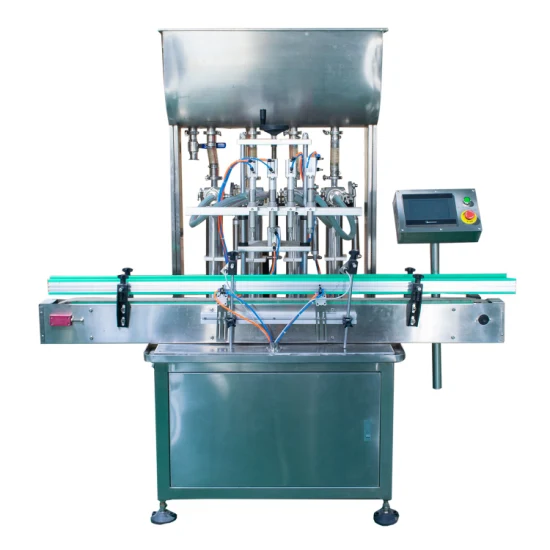

This equipment consists of six parts, namely uncoiling, forming, cutting, receiving, PLC control and hydraulic system.

| Main Parts: | |

| Manual Uncoiler | 1set |

| Feeding Guide | 1set |

| Roll Forming System | 1set |

| Hydraulic Cutting unit | 1set |

| Control system | 1set |

The next step is the cut-off part. This is generally two ways, electric and hydraulic. Electric is generally used in extreme weather, and hydraulic is more common. Hydraulic cutting has static cutting and servo tracking cutting, depending on the specific requirements. From the structure point of view, there are two forms of single guide post and double guide post. As the name implies, the stability of double guide post is stronger.

The next step is the cut-off part. This is generally two ways, electric and hydraulic. Electric is generally used in extreme weather, and hydraulic is more common. Hydraulic cutting has static cutting and servo tracking cutting, depending on the specific requirements. From the structure point of view, there are two forms of single guide post and double guide post. As the name implies, the stability of double guide post is stronger.

The hydraulic station control valve adopts large valves to prevent blockage. And it is equipped with an air-cooled system and is suitable for most areas.

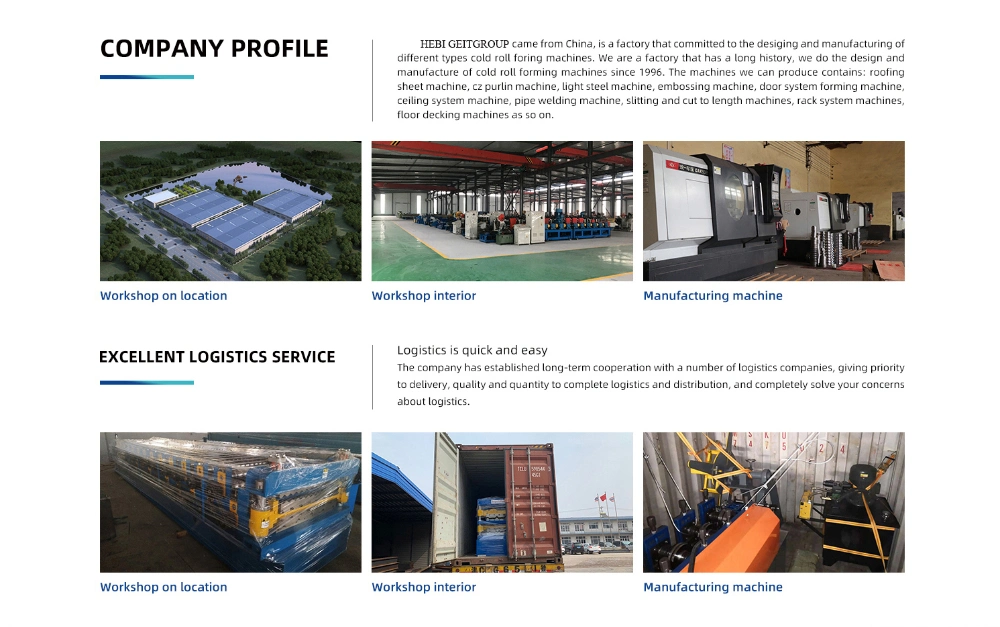

Main Products

Main products: Trapezoidal (IBR) roll forming machine , Glazed tile roll forming machine, Corrugated roll forming machine, Double layer roll forming machine, Ridge cap roll forming machine, Floor deck roll forming machine, C Z purlin roll forming machine, Keel roll forming machine, Roller shutter door roll forming machine, Highway Guardrail roll forming machine, Anti-condensation length machine.

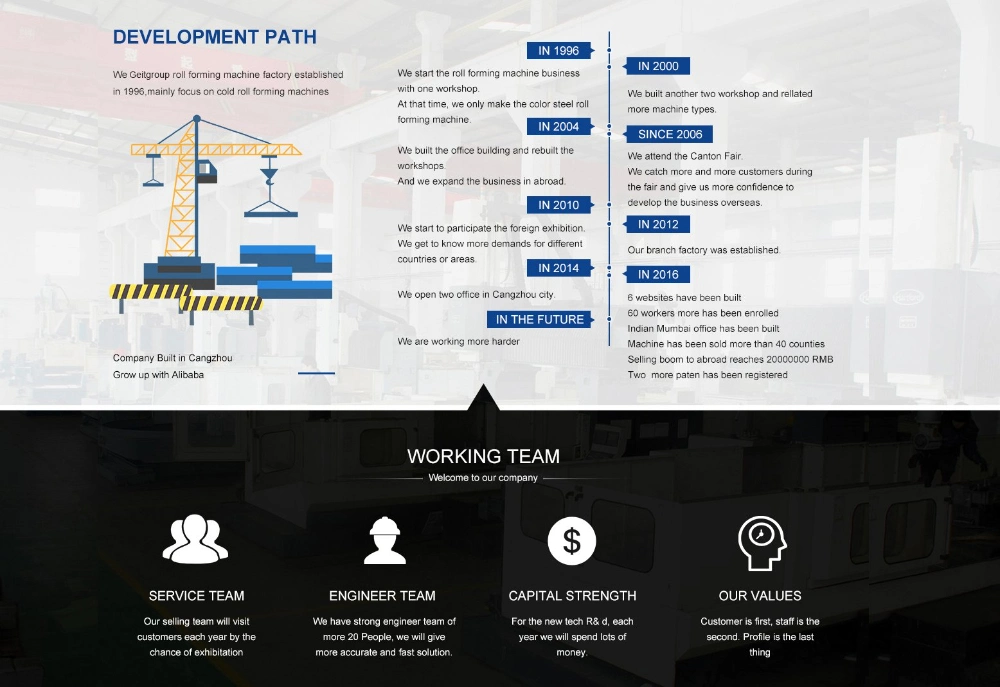

Our Team