Metal Roof Tile Ridge Cap Colour Coated Tile Roll Former Forming Pressing Making Machine

Basic Info

| Usage | Roof, Wall, Floor, PPGI,PPGL |

| Transmission Method | Hydraulic Pressure |

| Transport Package | Sea Worthy Package |

| Specification | 5.6*1.4*1.2m |

| Trademark | xinghe |

| Origin | China |

| HS Code | 8455221000 |

| Production Capacity | 3000 Sets/Year |

Product Description

Ridge cap Roof Roofing Sheet Roll Forming Machine

Technical parameters:

| Capacity | 5 tons |

| Feeding width | MAX 1000mm |

| Expanding range | 460-520mm |

| Main motor power | 4kw |

| Drive | 1'' single chain |

| Type | Wall board |

| Main shaft | ¢70mm |

| material | 45# forge steel and quenched |

| Roller material | 45# high grade forge steel ,chrome coated 0.05mm |

| Roll station | 13 groups |

| Raw material | 0.3-0.8mm |

| Coil width | 1000mm |

| Working speed | 10m--15m/min(Exclude cutting time) |

| Length Tolerance | ±1.5mm |

| Weight of machine | About 3 tons |

| Size of machine | About5600×1450×1200mm L x W x H |

| Color of machine | Yellow and Blue |

| Coder | Omron, made in Japan |

| Control | PLC . 380V 50HZ,3phase (Also depend on client) |

| Computer operating panel | touching screen |

| Other electrical element | |

| Cutting | Hydraulic cutting. Auto cutting when reach the set length |

| Hydraulic power | 3KW |

Equipment list :

| No. | Product Name | QTY |

| 1 | 5T Manual decoiler | 1 set |

| 2 | Includes Hydraulic cutting, PLC computer, Electrical cabinet, Hydraulic system | 1 set |

| 3 | Passive Output table | 1 set |

Character of main structure:

- The structure is simple and the appearance of the machine is beautiful because we adopt the shape-steel structure and most of the connectors are screw which make the machine flexible and stronger.

- All the components of machine are from brand-famous enterprise so that they ensure the machine normal function very effectively.

- We adopt the automatic length-fixed forming and cutting to guarantee the length to be precise and the finished product clear without deforming .

- It is very easy to install the equipment and suitable for producing in the factory.

- Low noise with high efficiency.

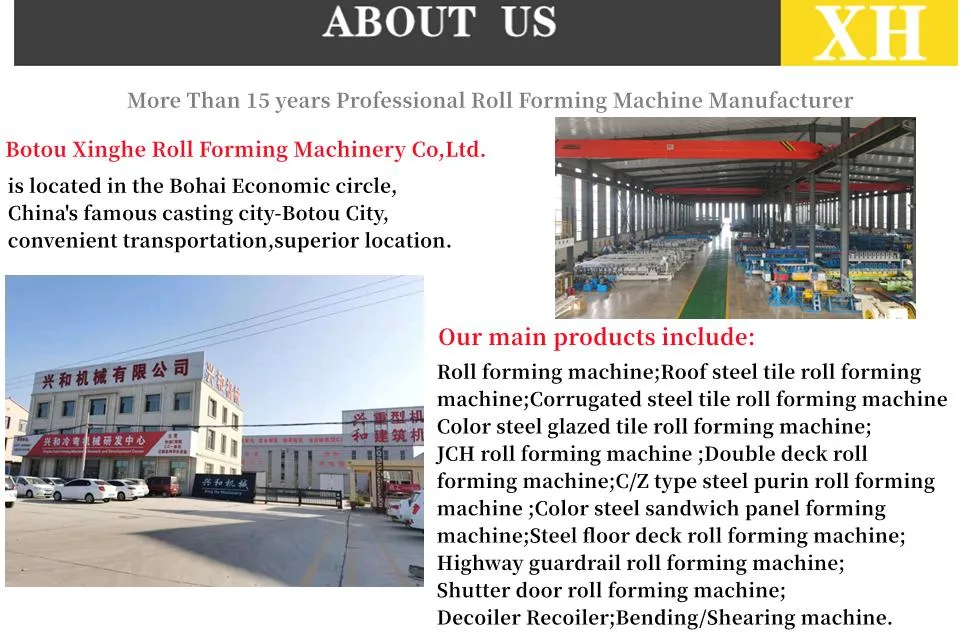

Botou XINGHE roll forming machinery is experienced manufacturer & exporter of cold roll forming machine with ISO quality system.Our R&D department is staffed with senior engineers who has more than 30 years experience in metal forming machine industry, so we are able to assist customers with professional designing and solution.Our range of products: roof tile roll forming machine, cold roll froming machine .cladding roll forming machine, metal decking roll forming machines, C/U/Z/W/L steel purlin roll forming machine etc. We also can supply steel coils, roof panels to suit diverse requirements of our global customers.Today, we have exported our machines to America, Chile, Mexico, Bolivia, Brazil, Colombia, Argentina, Ecuador, Honduras, Fiji, Papua New Guinea, Kuwait, Syria, Oman, Saudi Arabia, U.A.E, Nigeria, Tanzania,Ethiopia, Gana, Guinea,South Sudan, Algeria, Niger, Philippines,Indonesia,India, Azerbaijan and Kazakhstan.We have rich experience for cold roll forming machine solution,competitive price and excellent service. We will continue to do our best to supply perfect products and service for customers. Invite you to contact us for further information.

FAQ

1. How to get the quotation?

1.1.Give me the profile drawing and thickness,this is the important.1.2 Other specific requirements is welcome,such as the speed,power and voltage you want.1.3 If you don't have your own profile drawing, we can recommend some model types according to your local market standard.

2.Do you have after sales support?

Yes, we are glad to support advice. Our technicians available across the world.

3. Why your price is higher than others?

As we persist on that each factory should put quality at the first place. We spend a lot of time and money in the research and development of equipment and material selection, so that our machine is more automated, more reliable and accurate, and has a higher service life. Our equipment can last for nearly 20 years, and we offer a two-year warranty.

The machine will be tested before shipment with coil, ensure everything is ready 2.We will prepare some spare parts along with the machine, ensure our customer can solve the issue in a shortest time.Both the sale person and technician can give you the service overseas and make training for the workers,the sale person can make translation, so that the installation and training will be more clear and easily.