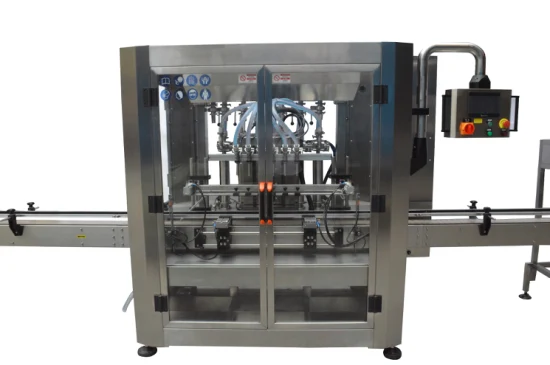

New Condition Small Water Filling Capping Machine with Bottle Gravity Bottling System

Basic Info

| Model NO. | CGF |

| Filling Principle | Vacuum |

| Packaging Container Lifting Structure | Chute Pneumatic Combination Lifting |

| Structure | Rotary |

| Packaging | Bottle |

| Packaging Material | Plastic |

| Composition | Mineral Water Plant |

| Material | SS304 |

| Certificate | Ce,ISO,SGS |

| Electrics | Siemens,Mitsubishi,etc |

| Control System | PLC with Touch Screen |

| Workshop Layout | Free Design |

| Bottle Volume | 200ml-2000ml |

| Capacity | 2000bph to 20000bph |

| Warranty | Two Years |

| Exchange Parts | Free |

| Transport Package | Wooden Case |

| Specification | 3.2m*1.8m*2.4m |

| Trademark | Proman |

| Origin | China |

| HS Code | 8422301090 |

| Production Capacity | 150machines/Year Mineral Water Plant |

Product Description

New Condition Small Water Filling Capping Machine With Bottle Gravity Bottling System Flow chart

1)water treatment system

Source water tank →Source water pump→ Quartz sand filter→ Active carbon filter→ Ion soften machine→ Fine filter →Reverse Osmosis → Ozone sterilizer → pure water tank

(Description: The processing flow adopted by a set of Pure Drinking Water Treatment System depends on quality of water source and target purpose of water usage. The selected flow basically includes three parts: pretreatment system, micro processing system and terminal processing system. The Pretreatment system includes multi-media filter, active carbon filter, softener, iron-manganese removal filter, ultra-filter, micro-filter, etc. The micro processing system adopts membrane filtration and ion exchange method. The terminal processing system involves in ozone/UV sterilization, iron exchange etc.)

2) Bottle filling & packing system

Pure water tank→Bottle blower→Air conveyor →Washing, filling & capping 3-in-1→ Light check → Full-automatic labeling machine → Ink jet machine →Full automatic PE film packing machine→ warehouse( Description: Spring cramps are used in the bottle washing process. The empty bottles can be turned over 180~ along the conveying rail. There is once time of internal and external washing, the efficiency of bottle washing is high.

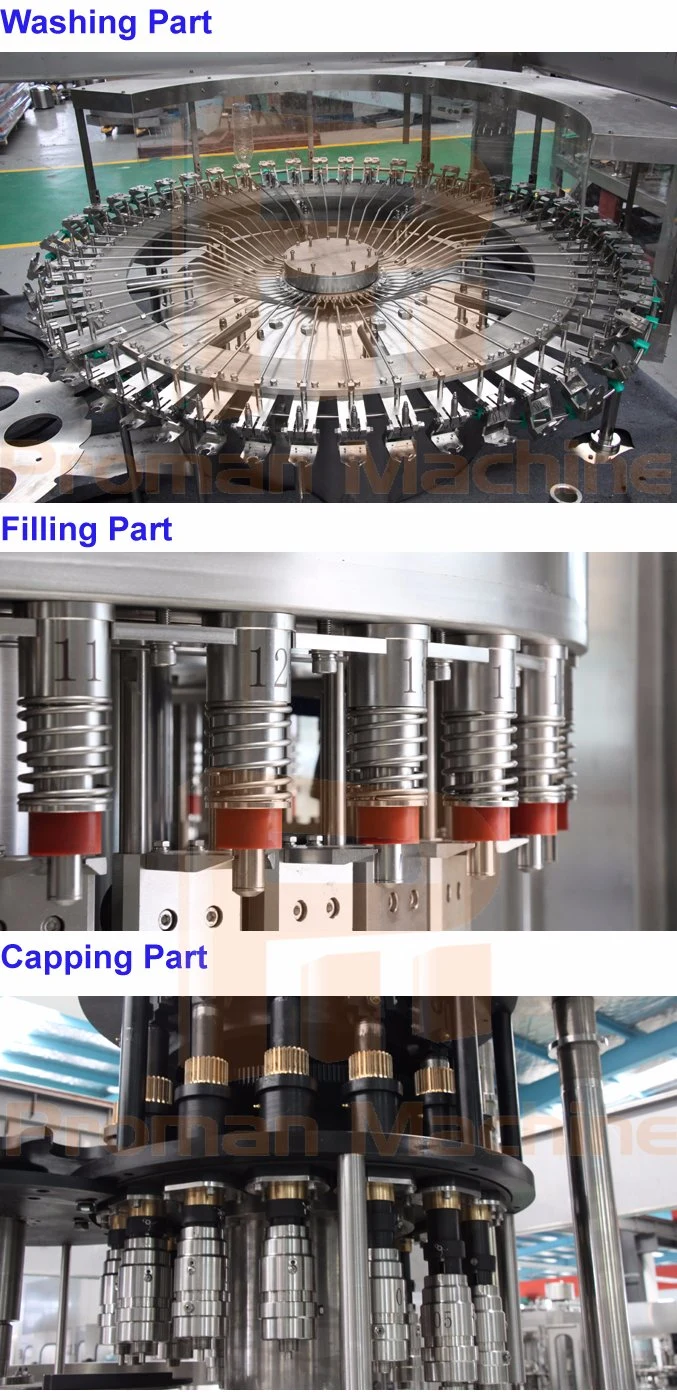

A) Washing part of Bottled Mineral Water Filling Machine:

l All 304 stainless steel rinser heads, water spray style inject design, save water consumption & more clean

lI 304 Stainless steel Gripper with plastic pad, ensure minimal bottle crash during washing

lII 304 stainless steel washing pump

B) Filling Part of Bottled Mineral water filling machines :

l High precision filling nozzle, PLC variable signal control, ensure high filling precision & filling smoothly & steadily,

lIFilling volume adjustable in fine rank, same liquid level after filling

lII All 304 stainless steel contact parts & liquid tank, fine polish, no death corner, easy to clean

lV 304 stainless steel filling pump

V no bottle no filling

C) Capping part of Bottled Mineral water filling machine:

l Place & capping system, electromagnetic capping heads, with burden discharge function, make sure minimum bottle crash during capping

lI All 304stainless steel construction

lII No bottle no capping,

lV Automatic stop when lack of bottle

Capability Character

It adopts hanging type conveying-bottle structure to make changing bottle more convenient,faster and easier.Themain machine adopts advanced PLC control technology.The key electric elements adopt international famous products.

Technical Character

| model | CGF8-8-3 | CGF14-12-4 | CGF18-18-6 | CGF24-24-8 | CGF32-32-10 | CGF40-40-12 |

| Number of rinsing head | 8 | 14 | 18 | 24 | 32 | 40 |

| Number of filling head | 8 | 12 | 18 | 24 | 32 | 40 |

| Number of capping head | 3 | 4 | 6 | 8 | 10 | 12 |

| (500m)Rated production capacity | 1000-2000 | 2000-4000 | 6000-8000 | 8000-12000 | 12000-16000 | 16000-20000 |

| (KW)Installed capacity | 3 | 3.5 | 4 | 4.8 | 7.6 | 8.3 |

| LxWxH(mm)Overall size | 1900×1420×200 | 2200×1600×2300 | 2450×1900×2300 | 2750×2180×2400 | 4600×2300×2300 | 4550×265×2300 |

| S.N. | Name | Remark |

| 1 | Washing head with bottle neck hanging | Made by our factory |

| 2 | Filling valve | Made by our factory |

| 3 | Sealing head | Made by our factory |

| 4 | Touch screen | Siemens |

| 5 | Transducer | Delixi |

| 6 | PLC | Siemens |

| 7 | Approach switch | Autonics |

| 8 | Light fiber switc | Autonics |

| 9 | Pneumatic elements | Airtac |

Certifications

FAQ

1.How to tell us your enquiry?

:You can contact us by email, phone call, fax, Instant Messenger (Trademanager, WhatsApp, Skype) and let us know your requirement.

2.Are you manufacturer or trading company ?

We are industrial manufacturer, which locates in Zhangjiagang city over 18years .

3.Where is your factory?

Our Factory is located in Zhangjiagang City, it is very near to Shanghai and Wuxi (airplame and train both available). If you arrive at Shanghai or Wuxi, we can pick you up to visit our factory.

4. Do you have any technical supports with your Beverage Filling Machines?

Yes, We have a professional team of engineers who owned many installation, debug and training experiences abroad, are available to service machinery overseas.

We Warmly Welcome Customers All Over The World To Our Company.If You Have Interests In Our Products. Please Contact Us If You Have Any Problems.