Hot Sale Gravity Working with Suck Back System Filling Packing Machine

Basic Info

| Model NO. | ZGP-6H |

| Filling Principle | Time Filling |

| Packaging Container Lifting Structure | Pneumatic Lifting |

| Structure | Linear |

| Packaging | Bottle |

| Packaging Material | Plastic |

| Machine Material | SUS304 |

| Contact Material | SUS 316 |

| Use | for Foamy Liquid |

| Filling Type | Gravity Time Filling |

| Transport Package | Wooden Case |

| Specification | 2440*1150*2300mm |

| Trademark | ZT-PACK |

| Origin | China |

| HS Code | 8422303090 |

| Production Capacity | 50sets/Month |

Product Description

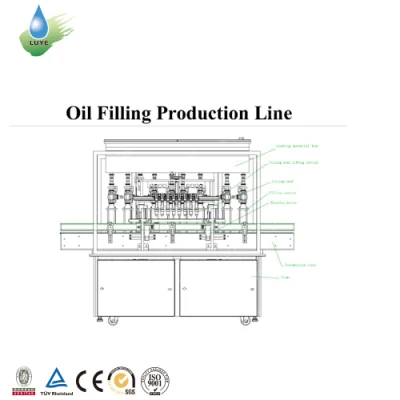

Automatic Gravity filling machine

Introduction: EC SL filling machine

This automatic paste filling machine adopts piston pump to do filling and driven by servo motor and by adjusting the position pump, it can fill all of the bottles in one filling machine, with quick speed and high precision and the speed can adjust according to your requirements

Charactreistic:

1.The automatic paste filling machine which contact liquid is made of stainless steel 304.

2.This automatic paste filling machine driven by servo motor that ensure filling with high precision and easy adjust for different kinds volume of bottle, like 200ml, 500ml, 1000ml -5000ml and can put them in same machine.

3.No bottle no filling and no capping

4.Capping head can easy change to suitable for different cap

For Foamy products packing , 100ml -5000ml

Parameter

| Product name | automatic gravity filling machine |

Productive Capacity | 20-100 bottles/min |

Applied Bottle | 100-500ml,500-2500ml,2000-5000ml |

Filling Tolerance | ≥0-1% |

Power | 3.5KW |

Power Supply | 380V/220V, 50Hz/60Hz |

Net Weight | 950kg |

Dimension | 2250(L)*1700(W)*1950(H)mm |

Famous brand electrical parts

Item | Name | Brand |

1 | Filling model | Aguer |

2 | Inverter | Mitsubishi |

3 | Touch screen | Siemens |

4 | PLC | Siemens |

5 | Main motor | ABB |

6 | low-voltage apparatus | Schneider |

7 | carrier plate | Japan POM plastic material |

8 | Air cylinder | Airtac |

Related Products:

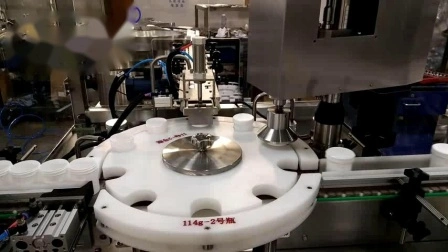

Linear Cap screw /Pressing Machine.

Bottle caps automatically goes into bottle caps slot by adopting cap-pulling device. In order to the machine can fit on capping on various bottle volumes, and considering multi-usages in this machine, so it is adjustable on machine design. It has more advantages on well-structure, good outlook, small volume, low weight, wide using range, easy dismissible and maintenance, and low quotiety of bottle broken.

Automatic Double Side labeling machine.

1.Adopt mature PLC control technology, make the machine stable and high-speed.Can be suitable or square /oval flat bottles at the same time.

2. Adopt touch screen control system, simple, practical and efficient operation.

NO.1 Adopt high quality wheel to leave some space between the bottles, so as to ensure that the labels will not be missed. The rotary speed of the sponge wheel can be adjusted to adjust space space between the two bottles.

NO.2 The parts of the machine that store labels and collect label paper are designed to be adjustable to accommodate a wide variety of labels.

NO.3 Adopt photoelectric equipment imported from Germany,and high quality servo motor, the labeling accuracy is greatly improved.

Company Introduction

<1> Standardized workshop of total 6,000 square meters. Different types of processing units, such as water jet cutter, plasma cutter, laser cutter, CNC machine from Taiwan chevalier & korea daewoo, ensure the precision of parts.

<2>International certification, National Certificate of equipment verification, and more than 30 invention patents are done in King machine . Verification Certificates of equipments: ISO9001:2001; CE Certificate , SGS,COC

<3>The equipment will be tested and run for 24 hours before leaving the factory, to ensure the smooth working of water pipeline, and pneumatic, electrical and mechnical stability.

<4>Sufficient stock of spare parts ensures the timely delivery and supply of spare parts.

<5>The engineers are experienced. We can produce different products with different capacity and work out reasonable flow chart as per customers' requirements to save space.

<6>Professional installation team who can speak fluent English can help customers make benefits in a shortest time.

Certificate:

Packing&Shipping:

FAQ:

Q1: Are you a machine manufacturer or trading company?

A1: We are a reliable machine manufacturer that could gives u best service. And our machine can be customized by client's request.

Welcome to visit our factory!

Q2: How do you gurantee machine normally operating?

A2: Every machine is tested by our factory and other client before shipping,We will adjust the machine to optimal effect before

delivery.And spare is always aviable and free for you in warranty year.

Q3: When can I get machine after I paid?

A3: We will deliver the machines on time as the date we agreed on both side.

Q4: How can I install machine when it arrives?

A4: We will send you manual books to you and if you need,also we have operate videos for each machines as well, we will send the engineers overseas to help client installing,

commissioning and training.

Q5: If I have different bottle of different diameter? Will the machine need extra moulds?

A5: No, the filling machine can be adjusted to suit different diameters bottles. Some capping machine needs to change molds for

different sizes cap.

Q6: Could I choose the language on touch screen?

A6: It's no problem. You can choose Spanish, French, Italian, Arabic, Korean, Japanese and etc,.Q1: Are you a machine manufacturer or trading company?

A1: We are a reliable machine manufacturer that could gives u best service. And our machine can be customized by client's request.

Welcome to visit our factory!

Q2: How do you gurantee machine normally operating?

A2: Every machine is tested by our factory and other client before shipping,We will adjust the machine to optimal effect before

delivery.And spare is always aviable and free for you in warranty year.

Q3: When can I get machine after I paid?

A3: We will deliver the machines on time as the date we agreed on both side.

Q4: How can I install machine when it arrives?

A4: We will send you manual books to you and if you need, we will send the engineers overseas to help client installing,

commissioning and training.

Q5: If I have different bottle of different diameter? Will the machine need extra moulds?

A5: No, the filling machine can be adjusted to suit different diameters bottles. Some capping machine needs to change molds for

different sizes cap.

Q6: Could I choose the language on touch screen?

A6: It's no problem. You can choose Spanish, French, Italian, Arabic, Korean, Japanese Russia and etc,.

Exhibition :

About us

Contact us :

Andy Lu (Sales)

Jiangsu ZhongTai Packing Machinery Co.,ltd

( ZT-PACK )

Address No. 2, He Shan Huan Road, Jintan District, Changzhou City, Jiangsu Province, P. R. China

Post Code : 213200

Mobile : 0086-13961141288

Tel:+86-519-82112618

Fax:+86-519-82113618

zt-pack.en.made-in-china.com