Bottle Making Gravity Filling Water Bottling Price Blow Fill Seal Machine

Basic Info

| Model NO. | BFC |

| Feed Cylinder Structure | Single-Room Feeding |

| Dosing Device | Surface Type |

| Filling Principle | Atmospheric Pressure |

| Packaging Container Lifting Structure | Chute Pneumatic Combination Lifting |

| Structure | Rotary |

| Packaging | Bottle |

| Packaging Material | Plastic |

| Suitable for | Water, Juice, Carbonated Drinks |

| Speed | 12000 Bph to 36000bph |

| Bottles Can Be Handled | 200ml-2L |

| Filling Accuracy | 0.05% |

| Core Components | Motor, Pressure Vessel, Pump, PLC |

| Function | Bottle Blowing Filling Capping |

| Keywords | Drinking Water Production Plant |

| Advantage | Running Steady |

| Feature | High Effective |

| Processing Types | Automatic Filling Production Line |

| Certification | ISO9001,ISO9000,CE |

| Material | SS304 |

| Transport Package | Wooden Case |

| Specification | 10000*3200*2750mm |

| Trademark | Sunswell |

| Origin | Jiangsu, China |

| HS Code | 8422301090 |

| Production Capacity | 50 Set/Sets Per Year |

Product Description

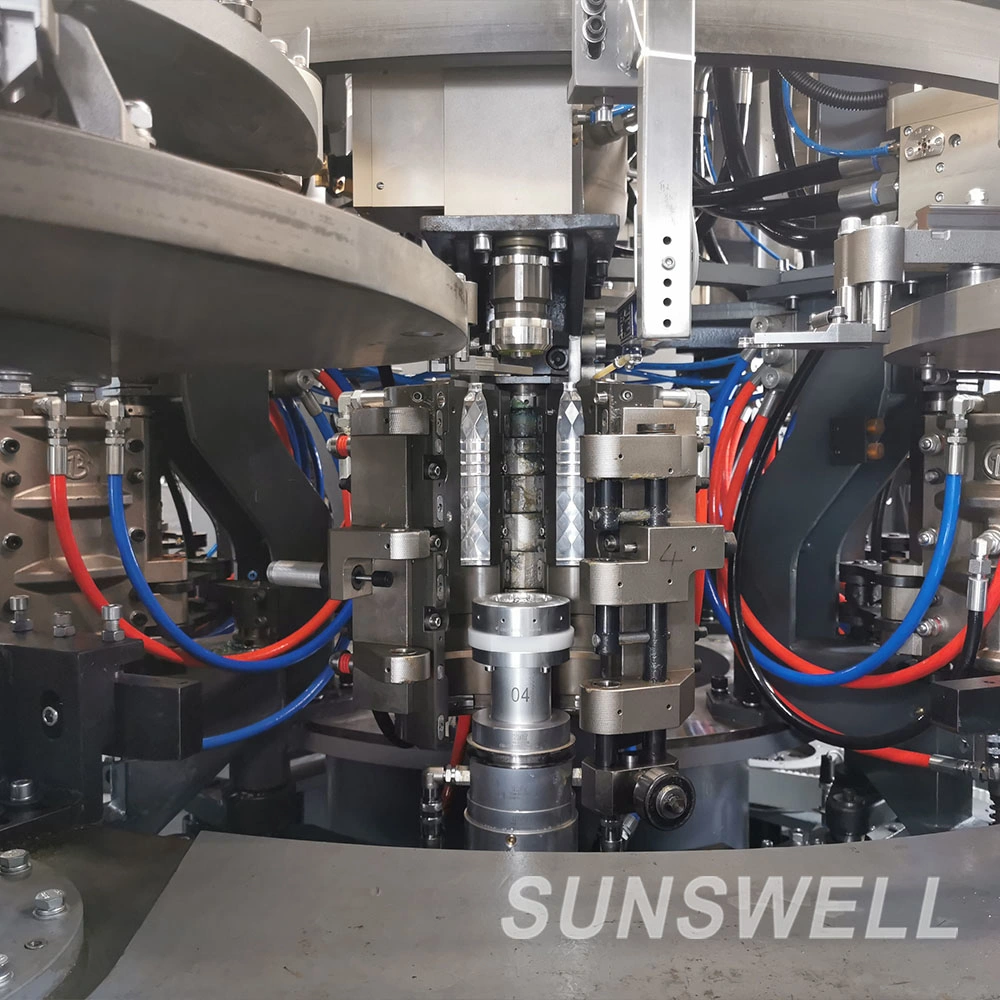

Sunswell is one of the leading Chinese able to manufacture high technology blowing-filling-capping machine in beverage business used in drinking water, juice, carbonated drinks area.

This combiblock consists of blowing unit, filling unit, and capping unit. With the synthetic application of electricity, mechanics, and pneumatics, and synchro controlled by servo system, Combi is applicable for the integrated control of several equipment and the whole production process.

| NO. | Model | Capacity | Remark |

| 1 | 8-24-8 | 12000bph | 500ml |

| 2 | 12-32-10 | 18000bph | 500ml |

| 3 | 16-40-15 | 24000bph | 500ml |

| 4 | 20-60-18 | 36000bph | 500ml |

1. Preform feed-in and unscrambling

It adopts the matured worldwide-standardized way of preform feed-in and unscrambling, in which preforms go through preform elevator and are transmitted to preform unscrambler. Inside the preform unscrambler, preforms are automatically sorted and delivered by two inclined revolving cylinders with same speed, and the remaining ones will be picked by star wheel and sent back to preform hopper. The whole process of preform unscrambling is fully automatic and has high efficiency without preform scratches.2. Heater

It adopts the matured worldwide-standardized way of preform feed-in and unscrambling, in which preforms go through preform elevator and are transmitted to preform unscrambler. Inside the preform unscrambler, preforms are automatically sorted and delivered by two inclined revolving cylinders with same speed, and the remaining ones will be picked by star wheel and sent back to preform hopper. The whole process of preform unscrambling is fully automatic and has high efficiency without preform scratches.3. Blowing unit

Special manipulator delivers heated preforms to moulds along certain cam curve. After stretch pre-blow, the preform will be blown to bottles by connecting high pressure compressed air. Special manipulator sends the finished bottle out along certain cam curve.4. Filling unit

The blow-made bottles are transported to filler via starwheel. After entering filler, the bottle is held by gripper of lifting cylinder and realizes up and down under effect of cam.The filler adopts gravity filling way. Bottle mouth rises to open filling valves and start filling. While product rises and plugs up air return hole, the filling will be finished. After filling, bottle mouth moves down and leaves the filling valve.5. Capping unit

Bottles enter capper via transition starwheel. The anti-rotation knife of capper blocks bottle neck to keep bottle vertical and prevent rotation. Capping heads keep revolution and do rotation. Under effect of cam, the action of gripping cap, sleeve cap, screwing cap and discharging cap to finish the whole capping course. The finished bottles are conveyed via bottle-out starwheel onto bottle-out conveyor, and then are sent out of the combiblock. The whole machine adopts console sealing windows, beautiful and decent.Company Profile

Q1: which city are you in? how can I get to your factory? Are you a trading company or factory?

A1: We are in Zhangjiagang city, two hours driving from Shanghai. We are factory. Manufacturing mainly beverage filling and packagingmachines. We offer turnkey solutions with more than 10 years experience.

Q2: Why is your prices higher than others?

A2: We offer high-end machines in our business. Welcome to our factory to have a visit. And you will see the difference.

Q3: What is your delivery time?

A3: Normally 30-60 working days depends one machines, water machines are faster, carbonated drink machines are slower.

Q4: How to install my machines when it arrives? How much the cost?

A4: We will send our engineers to your factory to install the machines and train your staff how to operate the machines If needed. Or you can arrange engineers to study in our factory.

You are responsible for air tickets, accommodation and our engineer wage USD100/day/person.

Q5: How long time for installation?

A5: Subject to machines and the situation in your factory. If everything is ready, it will take about 10 days to 25 days.

Q6: How about the spare parts?

A6: We will send one year enough easy broken spare parts together with the machines for free, we suggest you buy more units to save international courier such as DHL, it is really costly.

Q7: What is your guarantee?

A7: We have one year guarantee and life-long technical support. Our service also including machine maintence.

Q8: What is your payment term?

A8: 30%T/T in advance as down payment, rest should be paid before shipping. L/C is supported also.

Any more questions, pls feel free to contact me !